A ginning mill is a factory or plant, which majorly concentrates on the cotton ginning that involves making separation of the cotton fibers from the cotton seeds. Using ginning mills you will get pure cotton fiber without even the slightest of injury to seed or fiber. Hand separation of cotton fiber from seeds is now, replaced by a ginning mill.

Ginning stands for machining. Cotton ginning is the process of separating the cotton fiber from the cotton seeds. People used to do it manually years ago, but the evolution of Ginning machines has made the job faster and easier. Modern ginning mills produce the pure fiber without the slightest injury to either seed or the fiber.

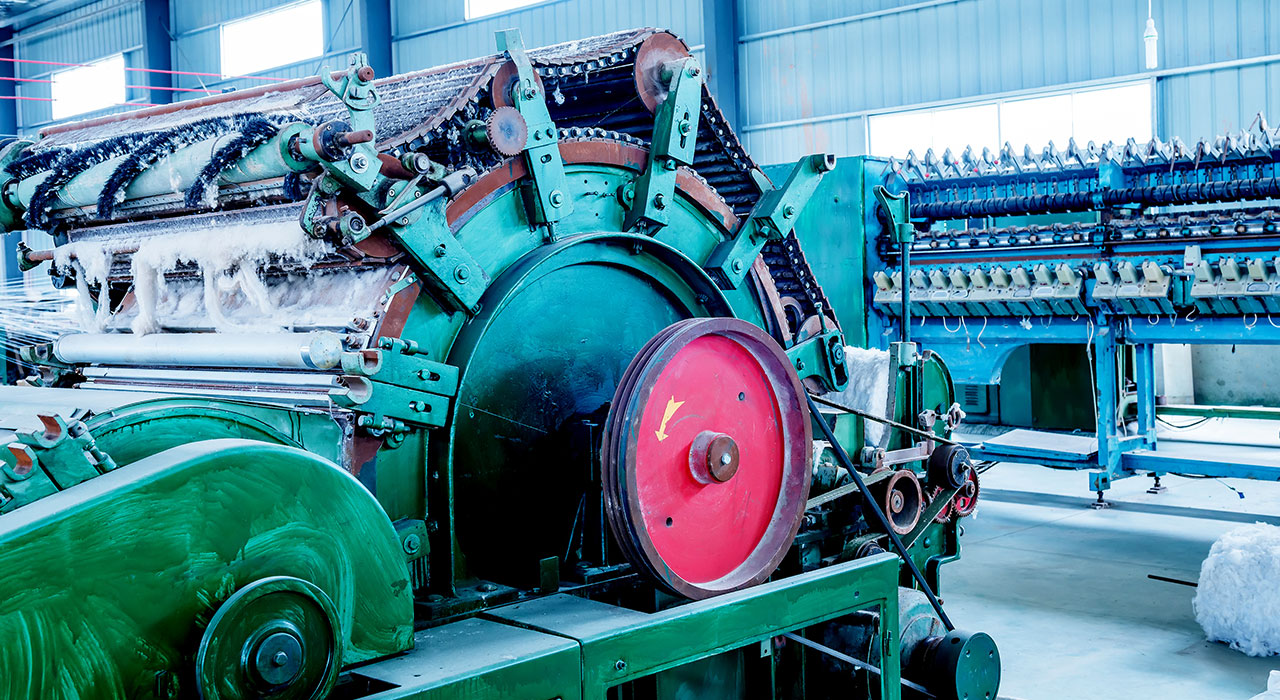

Working of Ginning Mills

Ginning is the first mechanical process of producing cotton. Cleaning, Spinning and Looming are the three main phases of cotton ginning. Fiber needs to get separated before cotton can be spun into yarn or thread and woven into cotton. Baxter flyers, Timing gear, Lock nut, Jute mill machine spindle, Jute mill pulley are the main parts of the ginning mill that make the ginning process fast and accurate. Stronger pulleys and steel teeth are used to separate the fiber from the seed. Belts, conveyors and pulleys are the main element of the ginning mill. A leather belt connected with bevel gear and pulley wheel passed through the ginning floor. Smaller pulleys attached to the belt turn the saw and brushes and that result into ginning the cotton.

Our Specialties

We are reputed manufacturer and exporter of Pulleys, Couplings and Taper lock bushes. We are specialized in designing low cost pulley that finds applications in various industries like ginning mill industry, rolling industry, rice mills, paper mill industry, oil and gas industry, etc. We offer a wide range of pulley to meet the specific requirements of the ginning mills. Based in Ahmadabad, Shree Shakti Pulleys supply the pulleys and couplings all across the India. We use the latest technologies to manufacture the pulleys that are perfectly shaped and balanced according to the current industry standers.

Our Core Competencies

- Advance manufacturing plant

- Industry leading prices

- Robust finished product output

- Accurate quality checking process

- Customized solutions for unique requirements

Get in Touch

Connect with us if you wish to discuss your next batch of job or next project